Bearings -

If bearings could talk...

by

Danny Spungen

ZeroDrag Bearings

Sep. 2001 Issue - Vol. 11 No. 8

We human beings have been in a battle against friction for thousands of years. Itís a battle of survival and as we skate into the 21st Century, ball bearings are taking on a life of their own.

Weíve come a long way. After man mastered the use of tools and fire, he attacked the problems of transportation. Sliding was the first form of transportation using water as a means to lubricate the two competing surfaces. Then some 6000 years ago in Central Asia the wheel was invented. From that day on, the laws of friction have kept us busy in our quest to move parts and people faster.

At one point in history, plain bearings were lubricated with human hairs that contained natural oil. Finally, the separate rotating parts in ball bearings have played a critical role since the late 19th Century in developing the lowest possible coefficient of friction of moving parts.

Not a week goes by without our company receiving questions on the "Doís and Don'ts" of caring for bearings. Bearings have taken on a life of their own, and if they could talk, would help clarify some of the marketing misinformation that has become prevalent.

Before a skater should worry about bearing care, he must determine if the bearing was well constructed in the first place. This is not an easy task given the variety of bearings on the market all claiming superiority.

What should you look for?

- How many balls are in the bearing? The popular 608 with 7 balls has a higher load rating than bearings made with 8 balls.

- Are the bearings manufactured with a superior finish? Rough raceways will wear out fast, regardless of how one cares for the bearings.

- How are the raceways shaped? The deeper the track, the better the bearing.

- What kind of seal design does the bearing incorporate? Contamination destroys the basic bearing properties.

Once a skater finds a good bearing, other important factors come into play that combine to create the lowest possible coefficient of friction. This includes considering what surface one is riding on, the environment, exposure to contamination, the quality of the wheel which has direct contact with the riding surface, and the design of the skates themselves.

I recently received an email from a speed skater saying how happy he was with his new bearings. He was able shed 7 seconds off his time. Surely, the bearings contributed to the success, but even a bearing salesperson (like myself) has to give credit to other factors as well.

Caring for Bearings

- Be realistic about the life you want out of a bearing based on your level of competition. Recreational skaters do not need to pamper bearings as much as speed skaters who compete regularly.

- You must keep bearings clean. Period! Use one set of bearings for competition and another set for training. Do not skate in the rain. Avoid water at all costs. Water will rust bearings. Avoid high humidity.

- Lubrication is very important, but be careful. Lubricants attract dirt and contamination so itís more like a love/hate relationship. Use only a good very light speed oil to create a very thin layer of film between the ball and raceways.

When should you clean and re-lubricate bearings?

This is tough. When spinning the bearings, if you feel any grit or the slightest skipping, clean immediately. The same if you skate in wet or sandy conditions. The best way to test bearings is by holding the inner ring with a thumb and one finger. Then using the other hand, rub the outer ring against the inner ring and feel for dirt or contamination.

How to clean bearings

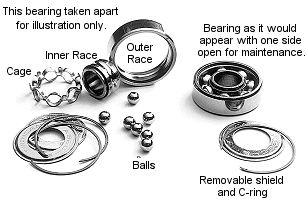

There are many opinions on this. The important point is to clean bearings in a clean environment, indoors rather than outdoors. The key is forcing out the dirt and the old oil lubricant. For those bearings with removable seals, remove with care. In our opinion, itís not worth the risk in trying to remove the retainer that holds the balls in place for those bearings made with this option. Before you add oil back into the bearing, make sure the bearing is dry with no cleaning solution still in the bearing. Cleaning solutions are not compatible with oils and will dilute their properties.

In conclusion, caring for inline skate bearings is just one of several important aspects in saving money and skating safely. By the way, this is probably the first bearing article you ever read that did not talk about ABEC ratings. For more information on inline skate bearings, visit http://www.zerodrag.com/